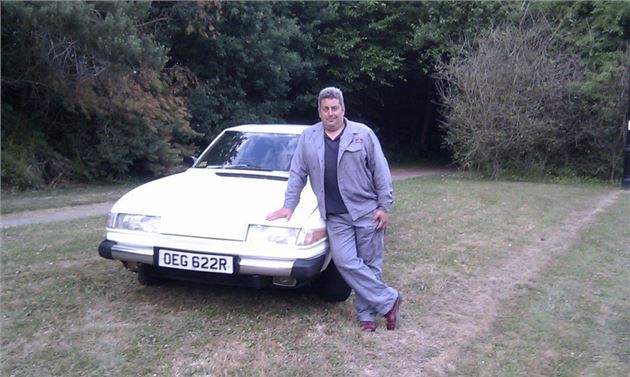

Our Cars: 1976 Rover 3500 SD1

3 February 2011: Pipes of peace (at last)

Keith’s Rover SD1 arrived for some badly needed TLC and emergency fettling. Arrival, that is, in the sense that I could hear Keith reversing off his drive in Northamptonshire three hours before he reached me.

The Polski-Rover’s exhaust was literally hanging by a thread on the passenger side cylinder bank and creating a noise that was scaring old ladies and making small children cry. The noise of a blowing manifold is, to me, possibly the worst kind of din – it’s right up there on my list of hated noises along with slipping fan belts, Bananarama, Sandi Toksvig and the Scouse accent.

Once, a while ago in my 1985 Maestro 1.3HL, the down-pipe sheared off where the two pipes go into a ball joint when I had an 18 mile drive from Daventry to Wellingborough late one evening. The noise was so bad I was almost in tears and, utterly embarrassed, I ended up pushing the ruddy thing the final 100 yards to my home to avoid a kicking from the neighbours which would have added further insult to injury – oh happy days!

Historically, exhausts and I don’t get on - there have been just too many occasions where my wrist would be welded to the downpipes on Austin Metros owing to intense heat or I’ve heard the shrieking sound of another stud snapping on the manifold of a 2.0 Montego to leave a taste even more bitter than lemon juice in my mouth.

The other major issue with the Polski Rover was that the gearlever has become semi-detached from the gearbox resulting in a gearshift less accurate than Stevie Wonder playing darts whilst wearing boxing gloves. The journey Keith had to endure included a lengthy stint on the M25 and must have surely made drowning in vinegar a more pleasurable alternative.

Reversing the car onto my drive Saturday tea time had the local curtains twitching - an elderly resident remarked to me this morning that he thought a German Dornier bomber had been shot down. Thankfully, I have understanding neighbours and, besides, it tends to be my door they knock on when their car goes phut conk. However, as I don’t live in an area that resembles a location for the TV show Shameless, I try to keep the knocking, banging and cursing to a minimum.

Anyway, getting down to the noise issue, upon first glance, it looked really bad, with what seemed to be a gap of half an inch between the manifold and down-pipe partly blocked with soot and exhaust bog (putty) adding to the visual horror. Keith’s mate Kev Mills had bravely tried to quieten things down with a tin of trusty Holts Gun Gum but to no avail so the car was jacked up and out came the lead lamp.

I was told that the studs had stripped their threads but to say I was surprised by what was revealed would be an understatement. What I actually found were three healthy looking studs with only two nuts, one of them being finger tight. I was in luck - no need for an Oxy-Acetylene kit and my stud extractor, but I decided to remove the nearside manifold for a closer look and to clean up the mating surfaces.

The existing nuts came off the pipes with no shrieking or resistance and the bolts retaining the cast iron manifold to the V8′s alloy head also came away with no headaches. One thing did surprise me - there were no gaskets between the manifold and head. How the hell it had sealed especially with it being a mixed metal affair amazed me.

The bulk of the putty was cleared off with a wire brush leaving two non-standard sealing rings on the down pipes of the stainless steel system. After a close examination, I decreed the rings to be serviceable but the short length of the studs protrusion had me concerned. Using an M8 nut with a decent washer would cause the nut to not get a good bit of thread, which was the original cause of the problem. A ring round a few motor factors drew a blank trying to get brass nuts where once they were commonplace, so I brewed another tea and had a think.

I then remembered that, in a dark corner of a box of bits, I had some odds and ends left over from when I rebuilt a cylinder head for a Rover 416 and it came to me that the inlet manifold nuts were modified to a self-locking type. These M8 nuts have a 13mm head but a broad shoulder thus doing the same job as a substantial washer to boot. The manifold was refitted with some new branch gaskets and the down-pipe was attached with this type of nut and the Polski-Rover is purring once again.

I then turned my attention to the rotten gearchange - some one has ‘been at it’ in the past and broken the retaining cup that holds the gearlever into the box. The rose bush and ball deep in the selector housing had also worn out (a common fault with the LT77) coming adrift and making gearchanges as prescise as a cow on roller-skates. Think of an early Maxi with a cable gearchange – it was much worse!

A new bush, ball and clip kit from RV8 Engineering has transformed the quality and feel of the gear change beyond imagination, but I can only make a temporary repair to the lever retaining cap. ANYONE who has a spare gearlever for an early SD1 LT77 gearbox with an intact retaining cap that still has the hole for the bolt should PLEASE get in touch with myself or Keith Adams – our contact details can be found in the site index to the far left of the page.

The Rover is, nevertheless, now a pleasant place to be again. My drive to work was a joy with many admiring glances and comments at the petrol station. No longer are you subjected to the smell of fumes and a noise akin to a Lancaster taxiing for take off on idle. The only sounds you can hear in the cabin on tick over now are the creaking of my bones as a result of rolling around on my cold, damp driveway.

Outstanding jobs left to do include attending to a minor PAS fluid leak, a general fitness check for its upcoming MoT, repairing the punctured nearside front tyre and the removal of the hideous industrial-looking tow bar which ruins the Solihull Daytona’s handsome, timeless shape.

Right! Back to the grindstone!

« Earlier: Happy new year! Later: A handsome beast (bar none) »

Compare classic car insurance quotes and buy online. A friendly service offering access to a range of policies and benefits.